Time-to-market is critical for OEMs. Our Tooling will speed you to market.

Time-to-market is critical for OEMs. Our Tooling will speed you to market.

Faced with shorter lead-times, mold makers turn to Global Precision to supply custom mold bases — quickly — providing a competitive advantage by saving time in the mold design process, and the cost and resources required for in-house machining. Global Precision provides quality custom mold bases for injection mold, die cast dies, and metal stamped tooling ranging from 300 to 3000 ton press size.

Additionally, Global Precision Industries, Inc. provides expert technical support that delivers superior value-added service for your investment. Our project engineers and project managers have real-world mold design and mold building experience. We know the critical issues throughout the job. In the development process, our project engineers proactively review mold designs and offer technical input to reduce the amount of time needed to complete the mold design. We can administer a mold base building program from 3D models, reducing the amount of detailing needed on the mold design. This also enables us to foresee potential problems and prevent them.

The way to significantly reduce costs is to utilize custom mold bases with pockets, supports, returns, guided ejection, knockout pinholes, retainer bolts for your cavities and cores, and clearance for water lines already installed. Custom mold bases are available in a range of levels of completeness, depending on your needs. The more complete the mold base, the less work you will need to do after it is in house. The more complex, the more savings you will realize. Our experts can help you determine the appropriate level of completeness for your unique situation.

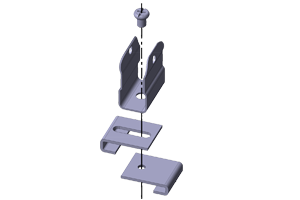

You can start saving additional time right from the initial stage by utilizing Global Precision’s expert design capabilities and logistics management to accelerate the process. The more you speed up design time, the quicker you get the mold base into your shop. Beyond delivering custom mold bases in a wide variety of sizes and complexity, Global Precision can supply mold components — like custom slide assemblies — that are engineered to fit in your mold building program. We can also supply cavity blanks, rough machined core and cavity blocks, and finish machining of large parting line contours. All are matched to your mold and are manufactured for interchangeability.

You can get the process started by contacting Global Precision Industries, Inc. to request a preliminary process layout. This will contain all-inclusive pricing with logistics and import fees included. We will also show a realistic, proven timetable to receive the products at your facility. Our process eliminates the time and resources needed by our customers to achieve complete compliance on the importation of your project.